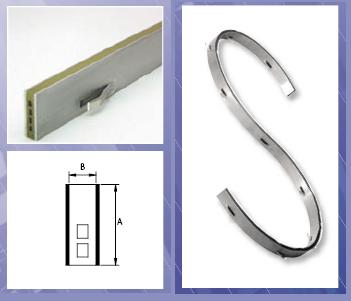

MORTARLOC Expansion Joints are designed for thick-bed

(mortar style) installations as opposed to thin bed installations

where Batex is primarily used.

MORTARLOC is manufactured utilising two side plates generally

1.2mm in thickness sandwiching a Neoprene infi ll in between.

The thickness of the side plates is normally determined by the

metal being used and the subsequent installation surrounds and

scenario. Thicker or thinner side plates can be used on request.

Mortarloc is manufactured in four standard metals;

Aluminium Brass Stainless Steel and Zinc.

The outstanding feature of the MORTARLOC Expansion

Joints is that unlike other available materials there are no

separate anchors required to hold the joint in place. The

anchors are part of the existing side- plate and are simply

bent out to 45 degrees during installation holding them in

the mortar bed.

MORTARLOC and BATEX Expansion Joints are not mechanical

movement joints and should only be installed where limited

movement within the fl oor covering is expected.

One of the major reasons for movement is temperature

fl uctuation caused by either seasonal change failure or

disconnection of airconditioning systems within closed buildings

or sudden downpours in tropical locations. All of which may

result in thermal expansion or contraction between .003mm

and .008mm per metre per degree centigrade temperature

fl uctuation. For basic calculations an average factor of .006mm

per metre per degrees centigrade is acceptable.

Mortarloc can be custom made to specifi cation i.e. radial

single-sided or multiple neoprene adhesion.

EXAMPLE

Temperature during installation 25?C

Expected Temperature rise 25ºC (to 50ºC)

Minimum Available Expansion on

Mortarloc with 6mm neoprene infi ll = 10%

0.6mm

0.006mm/m ºC x 25ºC = 0.15mm/m Expansion per line metre

Available expansion 0.6mm =4m (Distance between

Expansion per metre 0.15mm/m expansion joints

Mortarloc Thick-Bed Expansion Joints – Available in 1.8m lengths

Material Specifi cations:

SidePlates Used

Aluminium Alloy 6063

Brass Alloy 380/F

Stainless Steel Grade 304 / 316

Zinc

All of these materials have high tensile strength and good resistance to corrosion in an

industrial atmosphere

Neoprene – available in 6mm or 10mm widths

Colours

Black Grey Beige

other colours available on request

Hardness ASTM D2240 – Shore A 55

Tensile Strength ASTM D412 10 MPA

Elongation at Break 600%

Tear Resistance ASTM D624 28 Kn/M

Temperature Range -30?C to + 110°C

Acid Resistance – Concentrated Good

Acid Resistance – Diluted Excellent

Solvent Resistance – Hydrocarbons Good

Solvent Resistance – Oxygenated Fair

Oil & Gasoline Excellent

Animal & Vegetable Oils Good

Chlorine Fair

Citric Acids Excellent

Neoprene is universally recognised as having excellent resistance to deterioration from ozone

and weathering as well as high physical strength.

Please note that Neoprene can slightly discolour under extreme UV exposure. For more

information contact B.A.T. Trims Pty Ltd.

Adhesive

Softening Point 165? C

Normal Operating Temperature Range -60?C to +180?C

Tensile Sheer Strength 15-20 N/mm²

Humidity Resistance High

The adhesive used is specially formulated to bond Neoprene to metal

Reviews

There are no reviews yet.