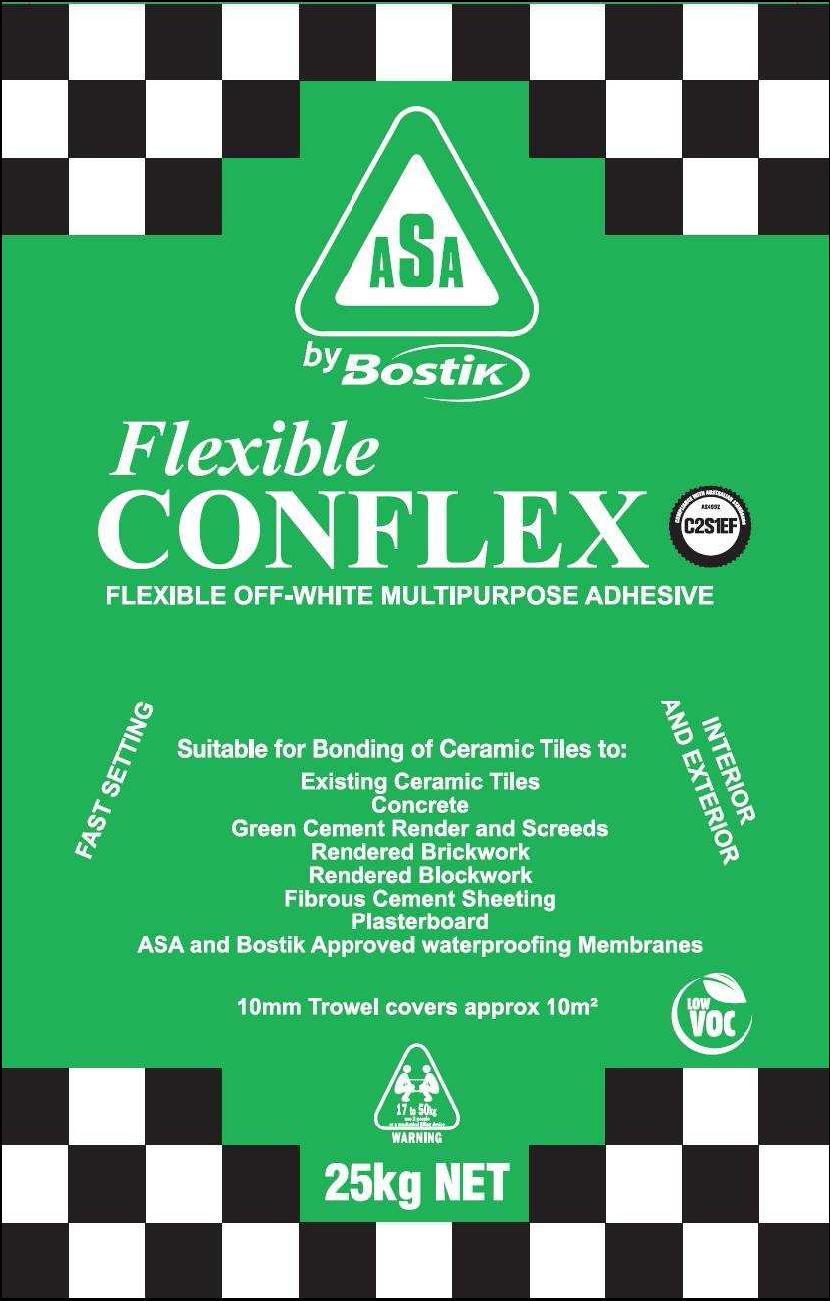

DESCRIPTION

Premium rubber-modified tile adhesive designed for demanding or high traffic applications. Excellent all-round adhesive suitable for commercial high traffic and tile-on-tile installations. Off-white colour.

CLASSIFICATION / STANDARDS

AS4992 CLASSIFICATION

C2 Improved” cementitious adhesive

S1 Deformable (flexible)

E Extended open time (>30 minutes)

FEATURES

- Excellent all-rounder

- Commercial Grade Suitable for Green Screeds and concrete

- Tile-on-tile all sizes internal

(300x300mm external)

BEST FOR

- General tiling

- When one adhesive is needed for most jobs

- Where a superior bond is needed

- High traffic

- Commercial or domestic

SUITABLE SUBSTRATES

- Concrete

- Render and early age (green) screeds

- Fibre Cement

- Plasterboard

- ASA Dampfix Gold ASA Dampfix 3 ASA Dampfix 2 and ASA Dampfix

- Wall and Floor

- High Traffic

- Commercial

SUITABLE TILES

All moisture stable tile types. Suitable tiles include porcelain ceramic terracotta terrazzo glass and stone.

SURFACE PREPARATION

1. Make sure the substrate has been correctly installed according to relevant standards and manufacturer recommendations

2. Allow for minimum curing time for screeds (1 day) and concrete (7 days)

3. Remove all materials that will interfere with bond. These include oils grease wax release agents curing compounds dust and any loose material

4. Ensure surface is sound. All weak or friable material must be removed

5. Check the cleaned surface by applying a small amount of water. It will be easily absorbed if porous and bead on the surface if not

6. Treat porous surfaces with a suitable primer designed for the task

7. Most non-porous surfaces may be primed with Bostik Ultra NP Primer

8. If tiling over existing tiles abrade the surface and clean well before tiling

Contact Bostik before commencing tiling if there is any doubt about required or suitable preparation.

MIXING

20 kg powder mixes into 5 to 5.5 litres of water

(1kg into 250 to 275mL of water)

1. add water to bucket

2. mix powder into water with mechanical stirring

3. mix until smooth

4. allow to stand for 2 minutes before using

Always add the powder to the water. Use a drill with suitable mixing paddle designed for the task. Do not mix by hand. .

APPLICATION

1. Apply to the prepared substrate using a notched trowel. Use a 6mm notch for tiles up to 150x150mm a 10mm notch for up to 250x250mm and a 12mm notch for 300x300mm tiles. Tiles 400x400mm and larger should be back-buttered in addition to using a 12mm notched trowel

2. Press tiles firmly into adhesive before it skins

3. Apply only up to 1m² at a time to avoid skinning

4. If skinned re-spread to expose wet adhesive

5. Check that at least 80% of the substrate and tile back are in contact with adhesive

6. Discard any material that has hardened before use

7. Allow adhesive to harden adequately before grouting

All workmanship must be carried out in accordance with AS3958.1-2007 and good workmanship practices

COVERAGE

On site coverage will vary widely as it is dependant on a large number of variables. These include but are not limited to: application technique substrate texture wastage trowel angle trowel wear contact coverage and flatness. As such the following coverage is intended as a guide only. As such coverage estimates are inaccurate. It is advised that comparisons between products are based on the mixed volume.

When mixed bag yields 18 to 19litres

Approximate Coverage (10mm trowel)

kg per m2 m2 per bag

2.8 7.0

GROUTING

Use a suitable ASA grout after the tiles appear firm. Modify grout with Megalastic when tiling is over a flexible substrate or when improved water resistance is required

CLEAN UP

Remove using a wet cloth before the product hardens. If allowed to set it must be removed mechanically

POT LIFE

3 hours at 22°C and 50% Relative humidity

SETTING TIME

6 – 8 hours at 22°C and 50% Relative humidity

Pot life and setting times will be influenced by ambient conditions. Shorter pot life and setting times should be expected in warm or dry conditions. Extra care should be in warm or dry conditions to ensure the adhesive has not stiffened significantly before the tiles are applied. Ensure that the open time has not been exceeded. If in doubt discard unused product and prepare a fresh batch.

STORAGE & SHELF LIFE

12 Months when stored off the ground in a cool dry weatherproof environment

AVAILABLE SIZES

25 kg and 14kg bags

PHYSICAL PROPERTIES

Appearance: Off White Powder

Mixed S.G: 1.51

SCAQMD | VOC %: <1

US RULE 1168 | VOC g/L: <1

Mixing ratio: 20kg into 5 5.5L

Pot life: 3hrs 22°C and 50% RH

Set time: 6hrs 22°C and 50% RH

Open time: > 30 mins

Appearance: Off White Powder

MECHANICAL PROPERTIES

Tensile strength: > 1.0 MPa

After immersion: > 1.0 MPa

Heat ageing: > 1.0 MPa

Freeze/thaw: > 1.0 MPa

Transverse deformation: > 2.5mm < 5mm

IMPORTANT NOTES

- All workmanship (including movement joints) must be carried out in accordance with AS3958.1-2007

- When fixing stone follow the recommendations in the Australian Stone Advisory Association (ASAA) Natural Stone Design Manual.

- Always read the entire Product Technical Datasheet before using

- Only tile surfaces that are suitable. If in doubt check with substrate manufacturer

- Always refer to the Material Safety Data Sheet (MSDS) before using

- When tiling directly onto waterproofing membranes check to ensure compatibility. If not already approved by Bostik in writing additional compatibility tests may be required

- If considering tiling over paint it must be well bonded clean and sound. Abrade and clean enamel paints. Prime before tiling.

- Use only ambient conditions between 5 and 35°C. Do not use in windy or very low humidity conditions

- Ensure that there are adequate falls when using on external or wet area floors.

- This product is not suitable for use with moisture sensitive materials.

- Not suitable for immersion (eg pools or water features)

- May be used to bond tiles to existing tiles. When tiling outdoors the tile size is limited to 300x300mm

- Ensure existing tile surface is sound and clean. Remove all cracked drummy or otherwise unsound tiles and repair area appropriately. Due to the possible variables extra surface preparation may be required (including mechanical abrasion). Contact Bostik before work starts for further advice if Contact Bostik before work starts for further advice if required.

- Some surfaces such as plastic and metal will require special preparation and may not be suitable.

- When tiling walls do not exceed 2.7m and always check that it will support the intended weight.

- Do not use to tile directly onto timber plywood particleboard MDF or masonite. Contact Bostik for advice before work starts if substrates or tiles are unusual or non-traditional or if there is any uncertainty regarding suitability or preparation

All workmanship (including movement joints) must be carried out in accordance with AS3958.1-2007

SAFETY PRECAUTIONS

SEE THE MATERIAL SAFETY DATA SHEET FOR ADDITIONAL INFORMATION.

Reviews

There are no reviews yet.