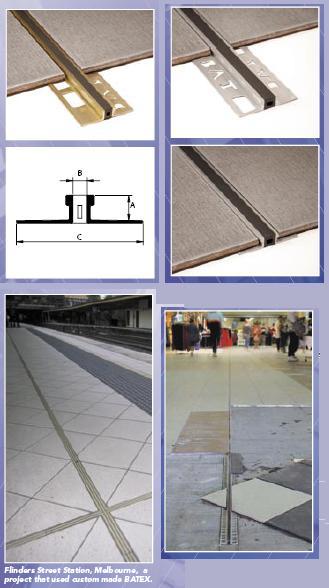

Batex Expansion Joints are manufactured from 3 individual

components Angle Neoprene infi ll and adhesive.

Batex Expansion Joints are designed for thin adhesive

bed installations where adhesive is able to penetrate the

perforated fi xing legs to hold them in place.

Each of the components have their own characteristics which

combined with an extensive manufacturing process produce

an Expansion Joint which minimises the risk of damage to tiles

caused by thermal expansion and contraction.

BATEX is manufactured in three metals as well as three

neoprene colours. Product dimensions (as per fi gure 1) vary

according to the materials used.

During manufacturing much care is taken to ensure proper

adhesion between the metal and the Neoprene. In order to

achieve a high tear resistance the Angles and the Neoprene

are mechanically and chemically prepared before the specially

formulated adhesive is applied.

The Expansion Joint is then left to cure under pressure for a

period of time.

After both materials are solidly bonded the Expansion Joint

is machined on the bottom to provide a fl at and smooth

surface and more importantly on the top to provide a level

fi nish between the Angle and the Neoprene.

The resulting fi nish is of PARAMOUNT IMPORTANCE for the

following reasons:

1. Hygiene

2. Safety Factors

3. Easy Cleaning

4. Avoidance of Damage

Batex Expansion Joints have been installed in numerous high

profi le projects both locally and worldwide. For more details of

projects where Batex has been used recently please contact us.

Easy installation is a feature of B.A.T. Trims entire range.

BATEX Expansion Joints are supplied in one prefabricated

easy to install three metre length. The ultimate feature of

BATEX is the long term maintenance costs that are minimised

by reducing the risk of tiles lifting or cracking.

BATEX can be custom made to specifi cation i.e. radial singlesided

or multiple neoprene adhesion.

Batex Thin-Bed Expansion Joints

– Available in 3m lengths

Material Specifi cations:

Angles Used

Aluminium Alloy 6063

Brass Alloy 380/F

Stainless Steel Grade 304 / 316

All of these materials have high tensile strength and good resistance

to corrosion in an industrial atmosphere

Neoprene – available in 6mm or 10mm widths

Colours

Black Grey Beige

other colours available on request

Hardness ASTM D2240 – Shore A 55

Tensile Strength ASTM D412 10 MPA

Elongation at Break 600%

Tear Resistance ASTM D624 28 Kn/M

Temperature Range -30?C to + 110°C

Acid Resistance – Concentrated Good

Acid Resistance – Diluted Excellent

Solvent Resistance – Hydrocarbons Good

Solvent Resistance – Oxygenated Fair

Oil & Gasoline Excellent

Animal & Vegetable Oils Good

Chlorine Fair

Citric Acids Excellent

Neoprene is universally recognised as having excellent resistance

to deterioration from ozone and weathering as well as high physical

strength.

Please note that Neoprene can slightly discolour under extreme UV

exposure. For more information contact B.A.T. Trims Pty Ltd.

Adhesive

Softening Point 165? C

Normal Operating Temperature Range -60?C to +180?C

Tensile Sheer Strength 15-20 N/mm²

Humidity Resistance High

The adhesive used is specially formulated to bond Neoprene to metal

Reviews

There are no reviews yet.